Company Timeline

From humble beginnings manufacturing radiator shutters, Varivane has grown in to a key supplier to the UK Ministry of Defence. Take a look below to see how we started and what we have become.

Throughout six decades, Varivane has provided support to more than 105 Royal Naval vessels, playing a crucial role in the UK's defence capability as a small to medium-sized enterprise, original equipment manufacturer, and provider of products and services. As we move in to a new era of naval shipbuilding, Varivane is primed and ready to continue our support to the Royal Navy and prime contractors.

From humble beginnings manufacturing radiator shutters, Varivane has grown in to a key supplier to the UK Ministry of Defence. Take a look below to see how we started and what we have become.

Established in 1964 in Sunbury-on-Thames, the company was named after a patented radiator shutter which was fitted to buses, trucks and military vehicles in order to help improve efficiency. Over the next few years our customer base widened to encompass both the automotive and defence sectors of the economy.

Varivane diversified to designing and manufacturing storage solutions for the UK Ministry of Defence, supplying the British Army with multiple ranges of equipment for tanks, armoured personnel carriers and fighting vehicles.

We moved to our current premises, a purpose-built factory and office unit in Devizes, in 1981. During the 1980s we were actively involved in the creation of the original NES128 design standard for the UK Royal Navy, helping to create a range of furniture that is still in use around the World today.

Varivane designed a new range of modular furniture as part of a habitability solution for all Royal Navy vessels, including: Type 22 Frigate, Type 23 Frigate, Type 42 Destroyer, HMS Ocean & Invincible Class Aircraft Carrier.

Varivane manufactured the accommodation and ammunition locker requirements for the Albion Class Landing Platform Dock. With HMS Bulwark and HMS Albion capable of carrying up to 405 troops, this was a significant project during which Varivane were proud to support the Royal Navy.

With the UK building six Daring Class guided missile destroyers, Varivane directly supplied BAE Systems with our ammunition lockers, codified furniture, security furniture and medical equipment.

Enter a new era of shipbuilding. Varivane supported the ACA (Aircraft Carrier Alliance) with the manufacture and delivery of key product ranges to HMS Queen Elizabeth and HMS Prince of Wales. From ammunition lockers to security furniture, and soft furnishings to accommodation solutions, Varivane played a huge part in the creation of the largest ships ever constructed for the Royal Navy.

Since the inception of DEF STAN 02-128 in the 1980's, Varivane have continued to support all existing Royal Navy vessels with product provision and technical support. Supplying directly to BAE Systems, Babcock International and the Ministry of Defence, Varivane continue to back our Armed Forces personnel with through-life support of key product ranges.

Varivane designed and manufactured the entire accommodation requirements for the INS Vikrant, the first aircraft carrier to be built in India. We delivered over 40 x 40ft shipping containers of furniture to Cochin Shipyard over a three year period.

Varivane manufactured the ammunition lockers, security furniture, medical complex and codified equipment direct to BAE Systems for the Type 26 program.

Varivane was awarded the contract for the accommodation package, habitability solutions, ammunition lockers, security furniture, life jacket lockers and associated equipment by Babcock International. Varivane have worked with Babcock from day one, providing design and consultancy services for this globally exciting new project.

As a trusted and approved supplier to the UK Ministry of Defence, Babcock and BAE Systems, Varivane is perfectly placed to utilise our unmatched experience and capabilities to satisfy multiple naval ship requirements. As the world moves in to a new global naval shipbuilding era, Varivane is ready.

We continue to hold the enabling contract from the Ministry of Defence for the manufacture and supply of furniture to Royal Navy legacy vessels. We supply directly to the Royal Navy, to all major UK shipbuilders, as well as to the global market.

We are currently assisting the Ministry of Defence in updating its furniture designs, including an equipment upgrade for the existing fleet and the improvement of equipment on new-build vessels.

A new generation of furniture is currently in development, based on the proven technical criteria and ergonomics of NES128, but updated to an improved and more modern aesthetic standard.

We export items throughout the world, and we are proud to celebrate 60 years at the forefront of our industry.

Varivane Industries is a member of the Society of Maritime Industries.

Our Senior Management Team (SMT) has worked at Varivane for an average of 27 years. We are subject matter experts within the industry and here to assist our customers with design, consultancy and full technical solutions

With more than 42 years of experience, I am deeply integrated into the Naval and Defence Industry. My extensive involvement with naval ship construction over the past four decades equips me to contribute significantly to the development of the next generation of warships on an international level. Leveraging this wealth of experience, I lead a distinguished team of industry specialists to deliver superior products and services to a prestigious customer base.

I have dedicated more than 26 years to Varivane, where I have engaged in a diverse range of responsibilities encompassing technical sales, business development, strategic growth, contract management, and project management. My extensive product knowledge spans all UK Naval platforms, and I serve as the primary point of contact for our clientele, having contributed to all UK naval vessels in service.

I commenced my career on the shop floor, subsequently progressing through roles in despatch and inspection. Currently, I hold the position of Shop Floor Manager, where I oversee the coordination of all production activities, collaborating with various departments to ensure that Varivane fulfills customer requirements and specifications

I have dedicated more than 27 years to my career at Varivane, acquiring unparalleled expertise in the procurement of specialised materials and components for the naval and marine sectors. My role involves collaboration with various departments to guarantee product and service quality while fulfilling customer needs through the provision of high quality materials and components.

I possess extensive experience as a design engineer and currently lead the design department at Varivane. I take great pride in having developed complete equipment ranges for the Type 31 project and the Hunt Class, as well as engaging in research and development initiatives aimed at advancing the company over the next ten years. With a remarkable attention to detail, I collaborate with end users, procurement teams, and the shop floor to deliver solutions tailored to naval and marine needs.

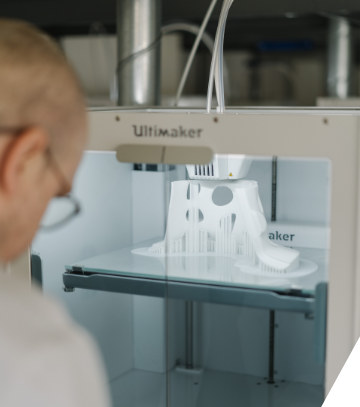

I have overseen the IT systems at Varivane for more than 15 years. Drawing on this expertise, I have been a crucial contributor to the design and development of essential Type 31 equipment. As a leader in the R&D department, I have facilitated Varivane's ability to engage in substantial 3D printing initiatives. Additionally, I am responsible for managing information security and ensuring compliance with Cyber Essentials standards.

I collaborate with all departments from an administrative perspective, executing vital tasks across various sectors of the organisation. As a valued team member, I am presently pursuing studies in accountancy to advance my career at Varivane. With nearly five years of experience at Varivane, I have developed an extensive understanding of our products, services, and processes, which allows me to operate effectively across multiple departments and provide exceptional service to both the company and our clientele.

Where bespoke items are required, clients can utilise the skills of our design & consultancy service, including design studies for through-life support, maintenance, and spares for new and existing equipment. If required, we can undertake on-site surveys. We provide a one stop service, all processes being performed in-house.

Varivane operates full fabrication facilities and machinery to produce a high quality product

Varivane operate a conveyor oven and spray booths to electrostatic powder coat products to any paint code

Varivane has a large assembly department built to handle high volumes of product, while assuring high product quality

Can’t see what you’re looking for? We offer a bespoke design & manufacture consultancy service, please get in touch with a member of our team to discuss your requirements.